Quality

Quality is central to all we do at Calman Technology. The company has had ISO9001 accreditation for twenty five years and we promptly completed our Transition Re-Certification July 2018.

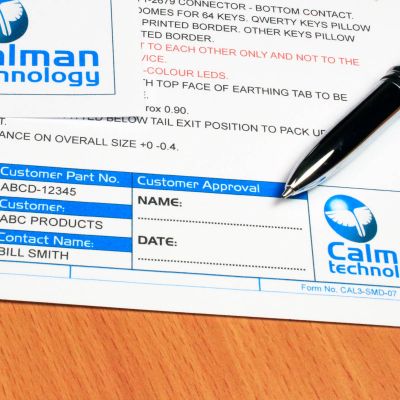

During manufacture of something as simple and straightforward as a two colour label, five or six inspection operations take place. Graphic overlays being a more complex product; including features such as display windows and embossing require additional inspection operations. In addition to formal inspection, operator vigilance and continuous management of every process guarantees high quality. All this manufacturing vigilance only begins after the client has approved the design drawings and internal inspection has been carried out on production “tools” such as photo plots and CNC cut files.

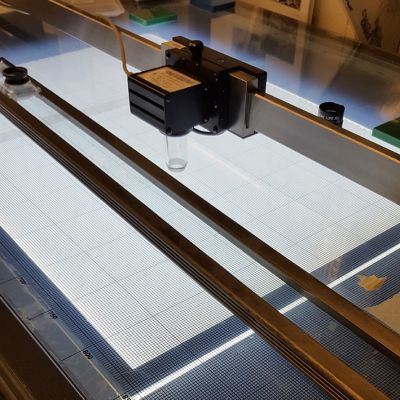

In membrane keypad manufacture the quality bar is raised even higher, so that in addition to in-process circuit inspection of insulators and conductors, all finished parts are 100% functionally tested prior to dispatch. As well as in-process inspection life test is carried out on an ongoing basis on all membrane keypad types.

- Colour Match

- Part Measurement

- 100% Functional Test for Membrane Keypads

- In-process insulation & resistance control